Efficient maintenance of main engine of the ship ensures smooth running, higher efficiency, and minimum breakdown. Main bearing of the main engine is one such part which can withhold the working of the whole engine if confronted with a fault. In this article we will have a look at the procedure for removal of main bearing of MAN B&W MC-C Engine.

Moreover, the main bearing of a ship’s main engine must be overhauled when its running hours as stated by the engine maker have been completed. Apart from this, if there is any sign of bearing worn out or if the bearing temperature is going high, it is imperative to open the main bearing for inspection.

The procedure for opening of the main bearing is as follows:

1) Inform company and take permission.

2) Take immobilization certificate from port state Authority stating that the main engine will not be available for a particular period of time.

3) Read the manual and have a toll box meeting with everyone involved in the job. Discuss the procedure.

4) Prepare important tools and spares to be used in operation.

5) Prepare risk assessment with the personnel involved in operation.

6) Shut starting air valve for main engine.

7) Open indicator cocks of all the units.

8) Engage turning gear and put it in remote control. The remote control switch to be operated by in charge of the operation.

9) Stop main lube oil pump.

10) Open crank case doors.

11) Put blower and ventilate it thoroughly.

12) Prepare enclosed space entry checklist.

13) After sufficient ventilation, wearing proper PPE enter the C/C.

14) Make sure that the main bearing measuring tool (depth gauge) is calibrate and set to ’0′.

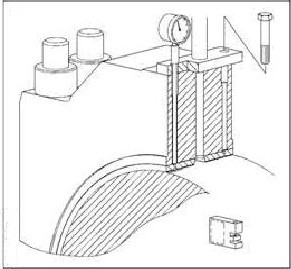

15) Open the screws of lube oil pipe connection and insert the depth gauge and measure the clearance between upper bearing keep and journal.

16) Compare this reading with the earlier reading in the record or the new bearing reading.

17) Now disconnect the lube oil pipe line.

18) Turn the crank throw so that it is towards the exhaust side.

19) Now mount the hydraulic jacks and loosen the main bearing stud nuts.

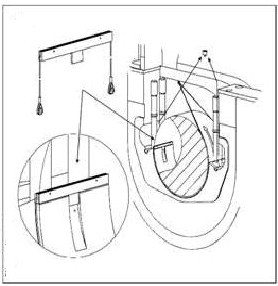

20) Mount the lifting tool for main bearing keep and lift the keep using a pulley and a wire rope.

21) Note the marking on the main bearing keep before lifting for correct direction of the keep.

22) Guide the keep safely outside with a help of another chain block and place it on a wooden base once it is out.

23) Mount the tool for lifting the upper bearing shell and place it safely outside.

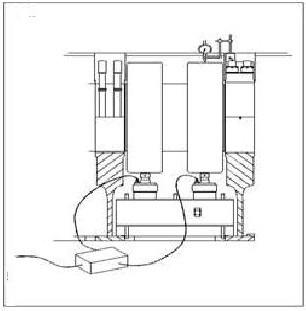

24) Place the strong back (cross piece) support on the bed plate so that its ends rest on the cross girders.

25) Mount the hydraulic jack on the cross piece placing it such that it lies beneath the crank webs.

26) Mount a dial gauge on the adjacent main bearing so that the lift of the crank shaft can be recorded.

27) Now with hydraulic pressure (1500-1650 bar) lift the crankshaft corresponding to the main bearing clearance to the adjacent main bearing, and check the lift with the help of a dial gauge.

28) Remove the lock screws from the lower shell.

29) Place the dismantling tool on the lower bearing shell such that the flap enters the oil groove.

30) Pull the bearing shell round and up so that it lies on the journal and take it out safely.

No comments:

Post a Comment